Magnetic Particle Testing

A method of detecting surface welding nonconformities in ferromagnetic welded connectors. This method is very accurate and efficient, it does, however, require careful preparation of the tested connector.

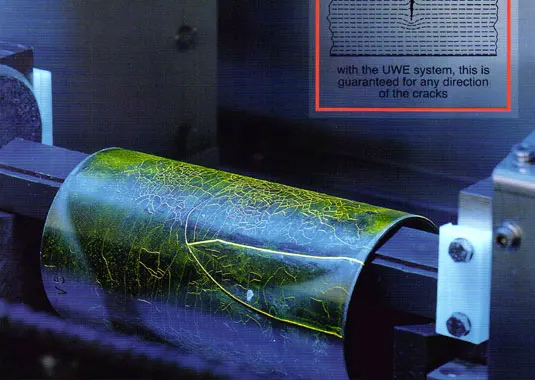

In this way, a longitudinal magnetic field would be able to be established in long items such as bars and cylinders. Circular magnetic field on the other hand is produced by allowing current flowing along the cylindrical material. Induction of magnetic field into the material to be inspected can be achieved by the use of either alternating current (AC) or direct current (DC). In general the use of DC would produce magnetic field deeper below that surface that allow subsurface discontinuity to be detected.

Discontinuities can be best detected when the direction of magnetic field is perpendicular. The chance of detection reduces as the angle between the magnetic field and the plane of defect decreases. When the angle between the magnetic field and the plane of defect is zero, i.e. the magnetic field is parallel with the plane of defect then the chance of detection becomes zero.

The application of MT involved the following sequence:

- Pre-cleaning

- Magnetization

- Application of magnetic powder

- Demagnetization

- Can provide the size of discontinuity detected

Advantages

The advantages and limitations of using MT method are as follows:

- Applicable only to ferromagnetic materials

- Insensitive to internal defects

- Require magnetization and demagnetization of materials to be inspected

- Require power supply for magnetization

- Coating may mask indication

- Material may be burned during magnetization

Limitations

- Applicable only to ferromagnetic materials

- Insensitive to internal defects

- Require magnetization and demagnetization of materials to be inspected

- Require power supply for magnetization

- Coating may mask indication

- Material may be burned during magnetization